In this study, a graphical single-line diagram (SLD) was constructed to represent the electrical network of a small-scale Coal-Fired Steam Power Plant (CFSPP). The diagram integrates both overhead and underground cable systems, allowing comprehensive modeling of the entire distribution network.

The analysis scope included:- Load Flow Calculation – Determining active and reactive power distribution across the system, identifying voltage drops, and assessing network efficiency.

- Short-Circuit Analysis – Evaluating fault currents for various fault scenarios to ensure protective devices operate within safe limits.

- Motor Starting Studies – Assessing voltage dips and system stability during large motor energization.

- Transient Stability Simulation – Examining system response under dynamic disturbances.

- Protective Device Coordination – Verifying settings to ensure selective and reliable fault clearance.

- Cable Derating Assessment – Applying temperature, grouping, and installation condition corrections to cable ampacity.

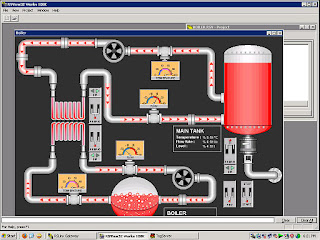

All circuit element properties—including transformers, circuit breakers, cables, and loads—were directly editable from the single-line diagram or underground raceway interface. This streamlined design allowed real-time calculation results to be displayed on the diagram itself, providing immediate visual feedback for engineering decisions.

Interpretation of Load Flow ResultsThe single-line diagram reflects real-time electrical parameters at each major node in the system, allowing direct insight into the operational performance:

- High Voltage Bus (HV Bus) – 70 kV, 1600 A, 31.5 kA

- Acts as the main distribution backbone for the plant.

- Load flow shows 99.7% efficiency, meaning voltage drop is minimal.

- Reactive power compensation is visible with kvar values near zero balance.

- Step-Up Transformer (7.2 kV → 70 kV) –

- Responsible for transmitting generator output to the HV grid.

- Load at secondary side: ~9940 kW, 6160 kvar.

- Transformer loading is within safe operating range.

- Generation Unit – 12 MW nominal capacity

- Actual load recorded: ~11310 kW (≈94% of nominal).

- Reactive power demand: 7998 kvar, managed by system capacitors.

- Generator operates at ~99.9% voltage regulation, indicating stable excitation control.

- Auxiliary Transformer (UAT) – 1121 kVA

- Supplies plant auxiliary loads (lighting, pumps, control systems).

- Efficiency ~99.8%, minimal losses.

- Bus and Feeder Segments –

- Each segment annotated with MVA, MW, and Mvar readings, plus efficiency %.

- Any percentage <98% would be a red flag for excessive voltage drop or line loss.

- In this case, all readings are ≥99.7%, meaning system is well-balanced.

- The system is optimally designed for its load profile, with high efficiency across all buses.

- Reactive power flow is well-managed; kvar values are within compensable limits, reducing the risk of low power factor penalties.

- Cable loading and bus voltages confirm that no part of the network is overstressed.

- The single-line diagram doubles as a live dashboard—both a documentation and monitoring tool.